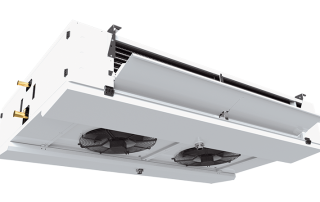

- COIL

• 16 mm copper or stainless steel tubes

• Aluminum fins, in the staggered and square geometry

• Fin distance 7 and 11 mm - TEST

• All coils are degreased, cleaned and tested for proper use.

• Maximum working pressure: 30 bar acc. to the Pressure Equipment Directive 2014/68/EU - CASNG

• Pre-painted aluminium and galvanised steel, white RAL 9016 coated

• Double drip tray

• Drip tray in aluminium-magnesium alloy, white RAL 9016 coated, foldable or removable

• Ceiling fixing feet in powder-coated galvanised steel white RAL 9016 - USE

• Tunnel

• Fast freezing with high air volumes

• Power up to 200 kW - FANS

• High-performance and energy-efficient axial fans, optional low-noise fans

• Protection class IP54 acc. according to EN 60529

• Temperature range -40 °C to 60 °C

• Internally overload protection wired thermal (TOP) - OPTIONS

• Stainless steel casing

• Pre-painted aluminum, magnesium aluminum or copper fins

• Protective coil treatments

- COIL

• 16 mm copper or stainless steel tubes

• Aluminum fins, in the staggered and square geometry

• Fin distance 7 and 11 mm - TEST

• All coils are degreased, cleaned and tested for proper use.

• Maximum working pressure: 30 bar acc. to the Pressure Equipment Directive 2014/68/EU - CASNG

• Pre-painted aluminium and galvanised steel, white RAL 9016 coated

• Double drip tray

• Drip tray in aluminium-magnesium alloy, white RAL 9016 coated, foldable or removable

• Ceiling fixing feet in powder-coated galvanised steel white RAL 9016 - USE

• Tunnel

• Fast freezing with high air volumes

• Power up to 200 kW - FANS

• High-performance and energy-efficient axial fans, optional low-noise fans

• Protection class IP54 acc. according to EN 60529

• Temperature range -40 °C to 60 °C

• Internally overload protection wired thermal (TOP) - OPTIONS

• Stainless steel casing

• Pre-painted aluminum, magnesium aluminum or copper fins

• Protective coil treatments